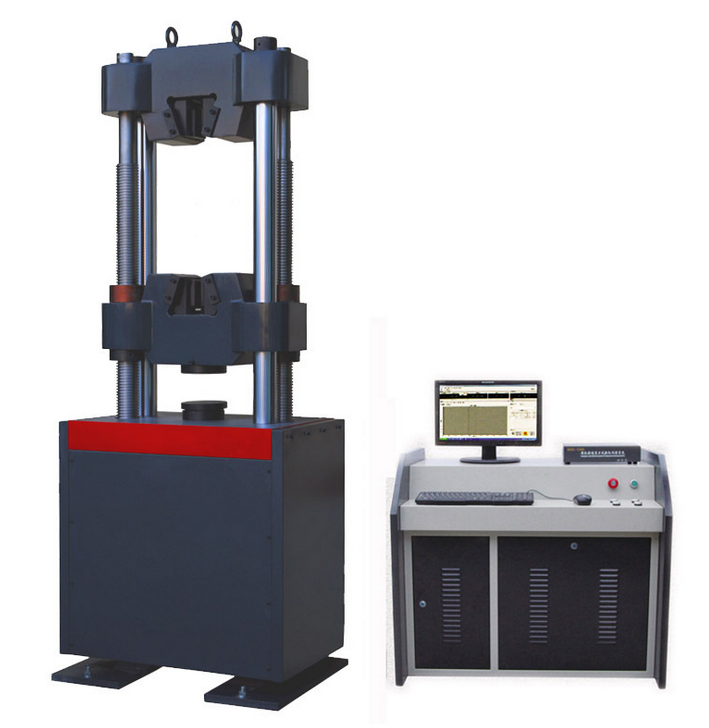

Hydraulic Universal test machine

Application:

hydraulic servo universal testing machine adopts a cylinder-mounted, double-column double-screw main engine, which is mainly used for tensile, compression, bending and shear tests of metal and non-metal. Applicable to metallurgy, construction, light industry, aviation, aerospace, materials, universities, research institutes and other fields.

Specification:

1. Maximum test force: 600kN;

2. Test force measurement range: 12KN-600kN;

3. Accuracy of test force indication: ±0.5%;

4, displacement measurement resolution: 0.01mm;

5, deformation measurement: standard configuration gauge length 50mm, the maximum deformation of 10mm.

6, deformation measurement accuracy: ± 0.5%

7, constant force, constant deformation, constant displacement control range: 0.4% ~ 100% FS

8, constant force, constant deformation, constant displacement control accuracy:

When the set value is <10%FS, within ±1.0% of the set value

When the setting value is ≥10%FS, within ±0.5% of the set value

9, deformation rate control accuracy: rate <0.05% FS is ±2.0% set value

Rate ≥0.05% FS is within ±0.5% of the set value

10, the maximum moving speed of the piston: 80mm / min;

11, the maximum tensile test space: 600mm

12, the maximum compression space: 550mm

13, flat sample clamping thickness: 0--15-30mm

14. Round sample clamping diameter: φ13- φ26-φ40 mm

15, pressure plate size: φ160 mm

16. Bending test roll spacing: 400 mm

17, piston stroke: 150mm;

20, clamping method: hydraulic clamping

21, sensor and amplifier: oil pressure sensor, inserted in the PC machine program-controlled amplifier, automatic zero adjustment, calibration

22, external dimensions: host: 730 × 570 × 1845mm

Oil source: 1020 × 620 × 810mm

23, the whole machine weight: 1800 kg

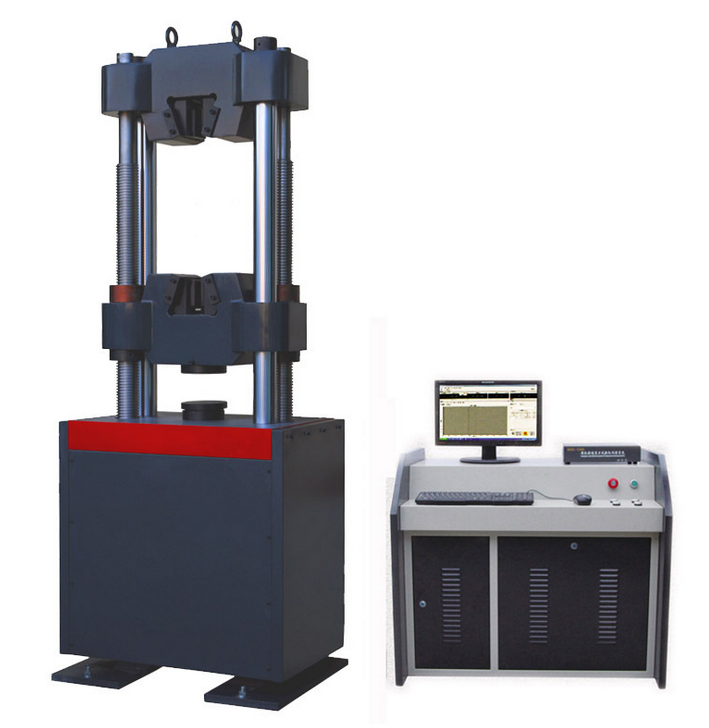

Hydraulic Universal test machine

Application:

hydraulic servo universal testing machine adopts a cylinder-mounted, double-column double-screw main engine, which is mainly used for tensile, compression, bending and shear tests of metal and non-metal. Applicable to metallurgy, construction, light industry, aviation, aerospace, materials, universities, research institutes and other fields.

Specification:

1. Maximum test force: 600kN;

2. Test force measurement range: 12KN-600kN;

3. Accuracy of test force indication: ±0.5%;

4, displacement measurement resolution: 0.01mm;

5, deformation measurement: standard configuration gauge length 50mm, the maximum deformation of 10mm.

6, deformation measurement accuracy: ± 0.5%

7, constant force, constant deformation, constant displacement control range: 0.4% ~ 100% FS

8, constant force, constant deformation, constant displacement control accuracy:

When the set value is <10%FS, within ±1.0% of the set value

When the setting value is ≥10%FS, within ±0.5% of the set value

9, deformation rate control accuracy: rate <0.05% FS is ±2.0% set value

Rate ≥0.05% FS is within ±0.5% of the set value

10, the maximum moving speed of the piston: 80mm / min;

11, the maximum tensile test space: 600mm

12, the maximum compression space: 550mm

13, flat sample clamping thickness: 0--15-30mm

14. Round sample clamping diameter: φ13- φ26-φ40 mm

15, pressure plate size: φ160 mm

16. Bending test roll spacing: 400 mm

17, piston stroke: 150mm;

20, clamping method: hydraulic clamping

21, sensor and amplifier: oil pressure sensor, inserted in the PC machine program-controlled amplifier, automatic zero adjustment, calibration

22, external dimensions: host: 730 × 570 × 1845mm

Oil source: 1020 × 620 × 810mm

23, the whole machine weight: 1800 kg