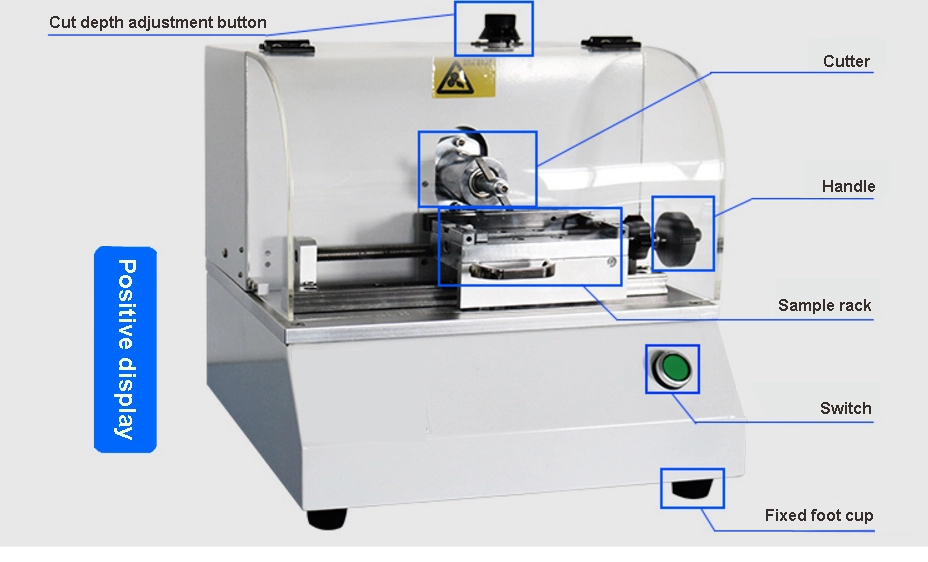

notch maker

Application:

This machine is for Izod and Charpy impact tester sample making.suitable for non metal material impact toughness test with notched specimen preparation equipment, notched impact of prototype equipment can be for scientific research institutes, tertiary institutions, non metal materials production plant and other units of the laboratory of notched specimens.

Test Standard:

ASTMD256-2010,ISO179—2000,ISO180—2001,GB/T1043-2008,GB/T1843—2008 JB/T8761—1998 JB/T8762—1998

Specifications

1) table stroke: > 160mm.

2) feed speed: 30mm/min.

3) sampling efficiency: more than 100 /10min.

4) feed amount: 0-2.5mm optional.

5) external dimensions: 450mm x width 390mm x height 360mm.

Characteristics:

1. can be clamping 20 samples, 100 samples making within 10 minutes.

2.Imported motor rotates smoothly and the tool is precisely calibrated.

3. High precision feeding:0.02mm.

Details:

Tool:

ØA type tool: 45±1 degree r=0.25±0.025

ØB type tool: 45±1 r=1.0±0.025

ØC1 type cutter: 45±1 r=0.1±0.02

ØC2 type cutter: thickness 1=2±0.1 r<=0.1

ØC3 type cutter: thickness 2=0.8±0.1 r=0.2±0.05

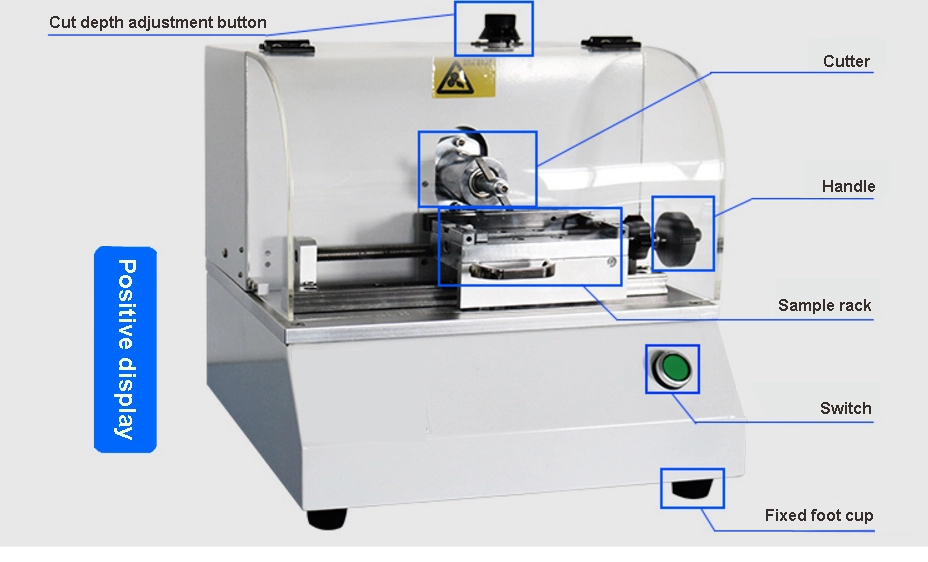

notch maker

Application:

This machine is for Izod and Charpy impact tester sample making.suitable for non metal material impact toughness test with notched specimen preparation equipment, notched impact of prototype equipment can be for scientific research institutes, tertiary institutions, non metal materials production plant and other units of the laboratory of notched specimens.

Test Standard:

ASTMD256-2010,ISO179—2000,ISO180—2001,GB/T1043-2008,GB/T1843—2008 JB/T8761—1998 JB/T8762—1998

Specifications

1) table stroke: > 160mm.

2) feed speed: 30mm/min.

3) sampling efficiency: more than 100 /10min.

4) feed amount: 0-2.5mm optional.

5) external dimensions: 450mm x width 390mm x height 360mm.

Characteristics:

1. can be clamping 20 samples, 100 samples making within 10 minutes.

2.Imported motor rotates smoothly and the tool is precisely calibrated.

3. High precision feeding:0.02mm.

Details:

Tool:

ØA type tool: 45±1 degree r=0.25±0.025

ØB type tool: 45±1 r=1.0±0.025

ØC1 type cutter: 45±1 r=0.1±0.02

ØC2 type cutter: thickness 1=2±0.1 r<=0.1

ØC3 type cutter: thickness 2=0.8±0.1 r=0.2±0.05