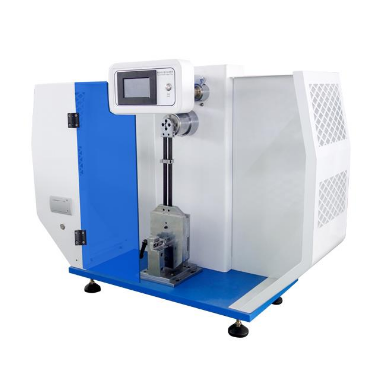

Charpy Impact Test

Application:

Charpy Impact Test Equipment can perform impact testing on hard plastics, fiber reinforced composites, glass fiber reinforced plastics, ceramics, asbestos and other non-metallic materials. Controlled by single chip microcomputer, electric hammer release, liquid crystal display impact energy, each group of samples can do one to ten, the test can be arbitrarily cut data.Automatic calculation of the strength, the average strength.Automatic printing of data reports.

Standards:JB/T8761, GB/T1043, ISO179, etc.

Characteristics:

1.The digital izod and charpy impact tester is a kind of intelligent digital testing machine using the microcomputer technology. It is advanced that it can automatically correct the energy loss caused by friction and windage to modify the energy chart, getting rid of the resistance effect. (The detection of the pendulum energy after specimen fracture and the correction of energy loss are finished during the impact at once)

2.The test results of digital izod and charpy impact tester are electrically displayed to make the reading more intuitive, improving the precision and accuracy of the impact machine.

3.The rotary encoder circular grating angle measurement technology is used by the instrument to display the thrusting energy, impact strength, pre-Yang angle, up angle, the average angle and the energy loss corrected automatically, with the advantages of high accuracy ,good stability and a large measure range.

Specification:

Model | A | B |

Impact Energy | 1J、2J、4J、5J | 7.5J、15J、25J、50J |

Impact Speed | 2.9m/s | 3.8m/s |

Pendulum Angle | 150° | 160° |

Distance From Center Of Pendulum To Center Of Sample | 230mm | 380mm |

Pendulum Torque | Pd1=0.5155N.m Pd2=1.0311N.m Pd5=2.5777N.m | Pd7.5=3.8662N.m |

Jaw Support Spacing | 40mm、60mm、70mm、95mm | |

Support Blade Fillet Radius | R=1mm | |

Angle Of Impact Blade | 30° | |

Impact Blade Fillet Radius | R=2mm | |

Accuracy Of Energy | 0.01J | 0.01J |

Technical Parameters

Impact speed: 3.5m/s

Impact energy: 5.5j (1J, 2.75j, 11J and 22J are optional)

Moment of impact pendulum: Pd1=0.535N·M

Pd2.75 = 1.4737 N · M

Pd5.5 = 2.9474 N · M

Pd11 = 5.8949 N · M

Pd22 = 11.7898 N · M

precision: Angle (0.01 °) energy (0.001 J)

pendulum Yang Angle: 150 °± 1°

strike center distance: 335mm

Radius of rounded corner of impact blade: 0.8 0.5mm

The distance from the impact blade to the top of the jaw: 22 0.2mm

Using temperature :15 to 35 ℃

Power supply: AC220 10% 50HZ

Sample type and size.The best sample is type 1, which is the preferred type.(mm)

Type A gap to 45 °±1 ° at the bottom of the hole radius R0.25 ± 0.05 mm

Type A gap to 45 °± 1 ° at the bottom of the hole radius R1±0.05 mm

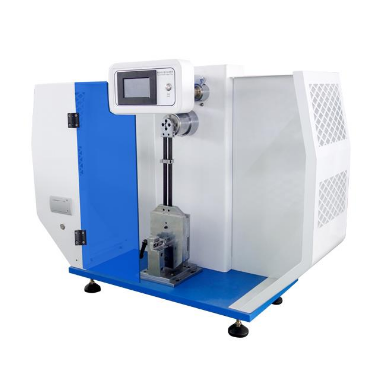

Charpy Impact Test

Application:

Charpy Impact Test Equipment can perform impact testing on hard plastics, fiber reinforced composites, glass fiber reinforced plastics, ceramics, asbestos and other non-metallic materials. Controlled by single chip microcomputer, electric hammer release, liquid crystal display impact energy, each group of samples can do one to ten, the test can be arbitrarily cut data.Automatic calculation of the strength, the average strength.Automatic printing of data reports.

Standards:JB/T8761, GB/T1043, ISO179, etc.

Characteristics:

1.The digital izod and charpy impact tester is a kind of intelligent digital testing machine using the microcomputer technology. It is advanced that it can automatically correct the energy loss caused by friction and windage to modify the energy chart, getting rid of the resistance effect. (The detection of the pendulum energy after specimen fracture and the correction of energy loss are finished during the impact at once)

2.The test results of digital izod and charpy impact tester are electrically displayed to make the reading more intuitive, improving the precision and accuracy of the impact machine.

3.The rotary encoder circular grating angle measurement technology is used by the instrument to display the thrusting energy, impact strength, pre-Yang angle, up angle, the average angle and the energy loss corrected automatically, with the advantages of high accuracy ,good stability and a large measure range.

Specification:

Model | A | B |

Impact Energy | 1J、2J、4J、5J | 7.5J、15J、25J、50J |

Impact Speed | 2.9m/s | 3.8m/s |

Pendulum Angle | 150° | 160° |

Distance From Center Of Pendulum To Center Of Sample | 230mm | 380mm |

Pendulum Torque | Pd1=0.5155N.m Pd2=1.0311N.m Pd5=2.5777N.m | Pd7.5=3.8662N.m |

Jaw Support Spacing | 40mm、60mm、70mm、95mm | |

Support Blade Fillet Radius | R=1mm | |

Angle Of Impact Blade | 30° | |

Impact Blade Fillet Radius | R=2mm | |

Accuracy Of Energy | 0.01J | 0.01J |

Technical Parameters

Impact speed: 3.5m/s

Impact energy: 5.5j (1J, 2.75j, 11J and 22J are optional)

Moment of impact pendulum: Pd1=0.535N·M

Pd2.75 = 1.4737 N · M

Pd5.5 = 2.9474 N · M

Pd11 = 5.8949 N · M

Pd22 = 11.7898 N · M

precision: Angle (0.01 °) energy (0.001 J)

pendulum Yang Angle: 150 °± 1°

strike center distance: 335mm

Radius of rounded corner of impact blade: 0.8 0.5mm

The distance from the impact blade to the top of the jaw: 22 0.2mm

Using temperature :15 to 35 ℃

Power supply: AC220 10% 50HZ

Sample type and size.The best sample is type 1, which is the preferred type.(mm)

Type A gap to 45 °±1 ° at the bottom of the hole radius R0.25 ± 0.05 mm

Type A gap to 45 °± 1 ° at the bottom of the hole radius R1±0.05 mm