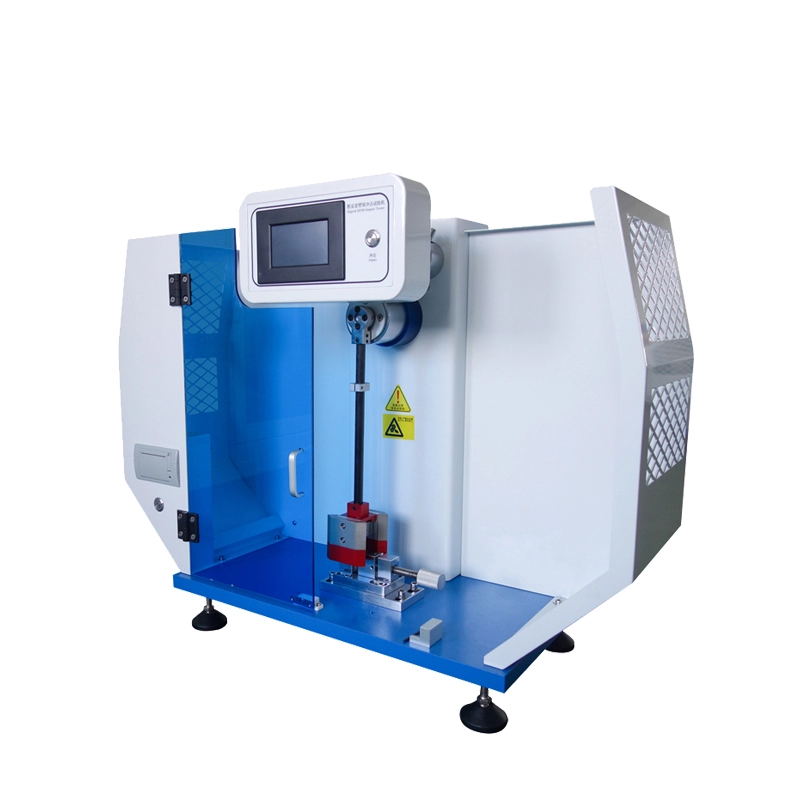

Izod/Pendulum impact tester

Izod/Pendulum impact tester of digital display cantilever beam is mainly used for the determination of impact toughness of hard plastics (including plate, tube, plastic material of the same kind), reinforced nylon, glass fiber reinforced plastics, ceramics, cast stone, electrical insulation materials and other non-metallic materials.Is the chemical industry, scientific research institutions, colleges and universities for material performance testing of the ideal test equipment.

Test Standard

ISO179-2000 "plastics - determination of impact strength of the simply supported beam with hard material,

JB/T8762-1998 plastic beam impact testing machine,

GB/T 18743-18743 "with thermoplastic fluid conveying pipe beam impact test method" (applicable to pipe)

ISO180-2000 "plastics - determination of hard material cantilever beam impact strength

GB/T1843-2008 "the hard plastic cantilever beam impact test method"

JB/T8761-1998 plastic cantilever beam impact testing machine,

ASTM D256-2010 "test method for determination of plastic the IZOD pendulum impact strength,

GB - T13525-1992 "plastic tensile impact test method for performance"

Technical Parameters

Impact speed: 3.5m/s

Impact energy: 5.5j (1J, 2.75j, 11J and 22J are optional)

Moment of impact pendulum: Pd1=0.535N·M

Pd2.75 = 1.4737 N · M

Pd5.5 = 2.9474 N · M

Pd11 = 5.8949 N · M

Pd22 = 11.7898 N · M

precision: Angle (0.01 °) energy (0.001 J)

pendulum Yang Angle: 150 °± 1°

strike center distance: 335mm

Radius of rounded corner of impact blade: 0.8 0.5mm

The distance from the impact blade to the top of the jaw: 22 0.2mm

Using temperature :15 to 35 ℃

Power supply: AC220 10% 50HZ

Test Sample:

Sample type and size.The best sample is type 1, which is the preferred type.(mm)

Type A gap to 45 °±1 ° at the bottom of the hole radius R0.25 ± 0.05 mm

Type A gap to 45 °± 1 ° at the bottom of the hole radius R1±0.05 mm

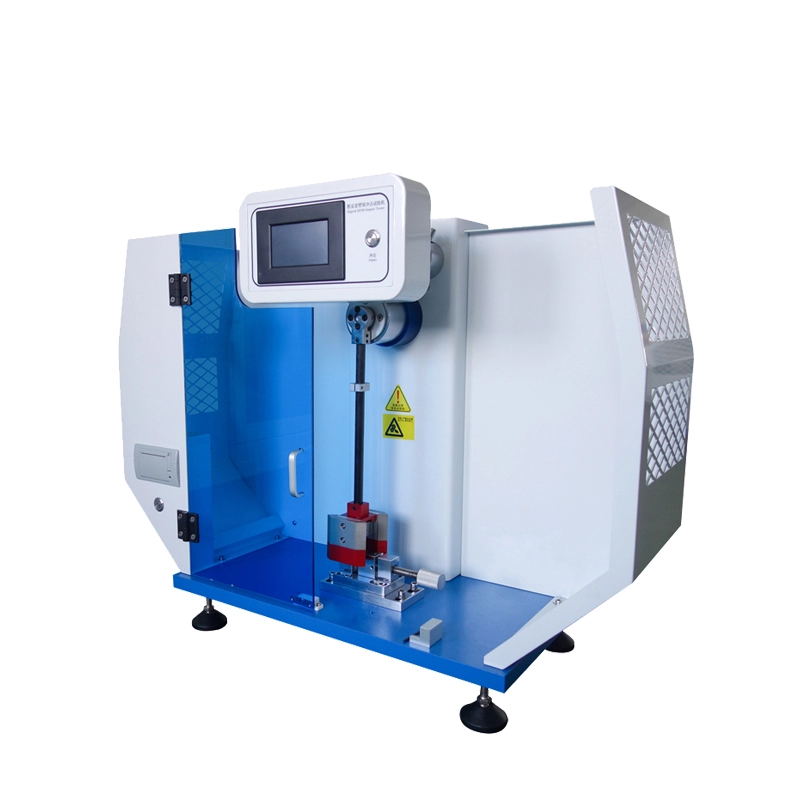

Izod/Pendulum impact tester

Izod/Pendulum impact tester of digital display cantilever beam is mainly used for the determination of impact toughness of hard plastics (including plate, tube, plastic material of the same kind), reinforced nylon, glass fiber reinforced plastics, ceramics, cast stone, electrical insulation materials and other non-metallic materials.Is the chemical industry, scientific research institutions, colleges and universities for material performance testing of the ideal test equipment.

Test Standard

ISO179-2000 "plastics - determination of impact strength of the simply supported beam with hard material,

JB/T8762-1998 plastic beam impact testing machine,

GB/T 18743-18743 "with thermoplastic fluid conveying pipe beam impact test method" (applicable to pipe)

ISO180-2000 "plastics - determination of hard material cantilever beam impact strength

GB/T1843-2008 "the hard plastic cantilever beam impact test method"

JB/T8761-1998 plastic cantilever beam impact testing machine,

ASTM D256-2010 "test method for determination of plastic the IZOD pendulum impact strength,

GB - T13525-1992 "plastic tensile impact test method for performance"

Technical Parameters

Impact speed: 3.5m/s

Impact energy: 5.5j (1J, 2.75j, 11J and 22J are optional)

Moment of impact pendulum: Pd1=0.535N·M

Pd2.75 = 1.4737 N · M

Pd5.5 = 2.9474 N · M

Pd11 = 5.8949 N · M

Pd22 = 11.7898 N · M

precision: Angle (0.01 °) energy (0.001 J)

pendulum Yang Angle: 150 °± 1°

strike center distance: 335mm

Radius of rounded corner of impact blade: 0.8 0.5mm

The distance from the impact blade to the top of the jaw: 22 0.2mm

Using temperature :15 to 35 ℃

Power supply: AC220 10% 50HZ

Test Sample:

Sample type and size.The best sample is type 1, which is the preferred type.(mm)

Type A gap to 45 °±1 ° at the bottom of the hole radius R0.25 ± 0.05 mm

Type A gap to 45 °± 1 ° at the bottom of the hole radius R1±0.05 mm