Automatic MFI Tester

Description:

This instrument with high precision instrument for the determination of all kinds of plastic, resin through a certain temperature and load in viscous flow state, each 10min by standard die melt flow rate MFR/MVR, polycarbonate, it is suitable for the high melting temperature polyarylsulfone, fluorine plastic, nylon and other engineering plastics, and is also applicable to PE PS, PP, ABS, POM, PC resin and other low melting temperature of the plastic test, is widely used in the production of plastic, plastic products, petroleum and chemical industries, relevant institutions, scientific research units and inspection department.

Standards: ISO1133-97, ASTM1238,GB/T3682-2000,ect.

Characteristics:

1.Three sections temperature control , 3 groups of platinum resistance sensor, 3 sets of separate heating temperature control, high precision intelligent PID control, warming slope heating speed is adjustable

2. Temperature resolution of 0.1 degrees, the temperature fluctuation within 24 hours does not exceed 0.5 degrees, the resolution of displacement sensor 0.001mm.

3. Temperature protection device

4.Automatic cutting & Manual cutting function.Can be arbitrarily set the cutting time(0~999), cutting the numbers (0~999).

5. Test can choose quality method, or volume method, or two kinds of test methods at the same time, and can calculate the flow rate ratio. The two methods are all tested when the piston rod moves to a certain position.

6. Can be set to 240 seconds (GB3682) material preheating seconds countdown, countdown to the end, automatic weight loading, loading to the specified interval to start the automatic cutting, can also set up American Standard (ASTM) such as the preheating time.

7. Built a variety of plastic melt index testing conditions, the convenience of customers at any time to obtain the use, reduce the tedious work, and store the last test conditions and results

8. Built-in printer to print the test data

9. High precision touch screen controller, 7 Inch Touch screen, can store and print the test conditions and test data recently, print menu including test time (default), material name, test conditions (temperature, weight, cutting time interval), the test result data.

10. Reserved for the RS232 interface or USB interface connected with a computer through the computer control instrument operation and the test data will be saved to the computer transmission,The weights are placed on the weight bracket in advance to realize the electric loading and unloading, and the manual operation is reduced.

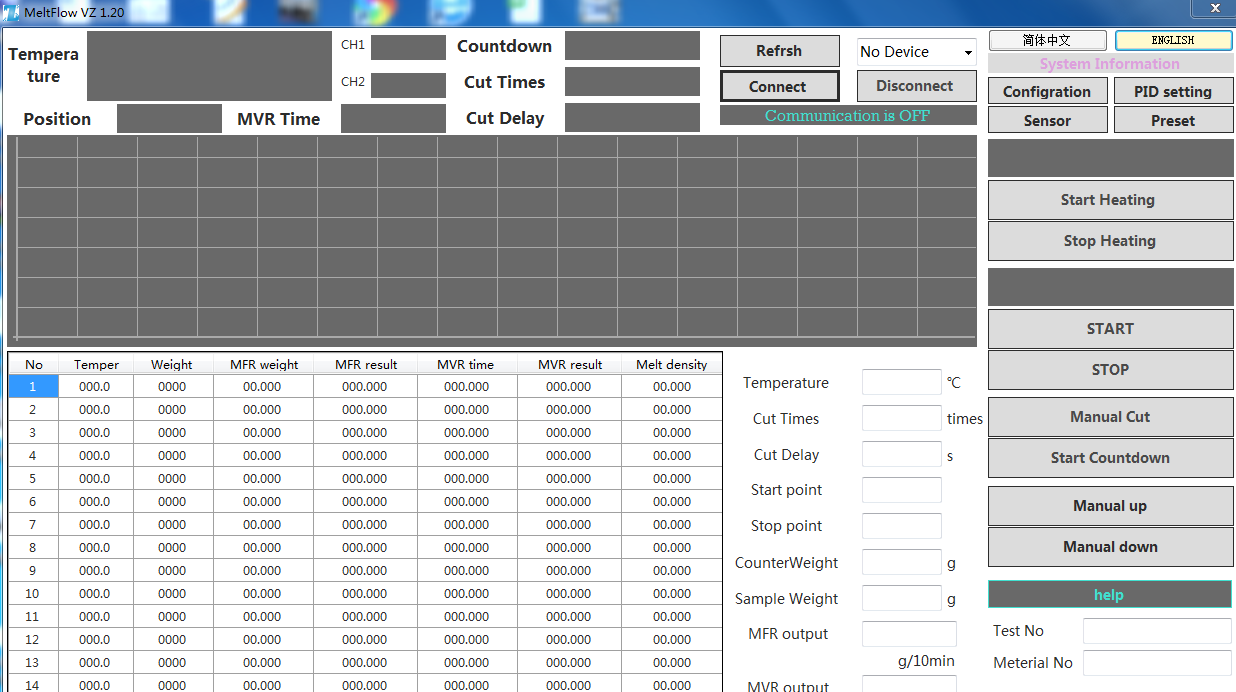

Software:

Technical parameter:

*Temperature range: 0 -450 C

*Temperature fluctuation: ± 0.2 centigrade

*Temperature uniformity:± 1

*Temperature display resolution: 0.1℃

*Time resolution: 0.1S

*Barrel diameter:Φ 2.095 ± 0.005mm

*Length of outlet: 8.000±0.025mm

*Barrel diameter: Φ9.550±0.025mm

*Weight accuracy: ±0.5%

*Output mode: micro automatic printing output

*The cutting way: automatic cutting & Manual cutting

*Test load: total of 8, 8 sets of weights

*The power supply voltage: AC220V± 10% 50HZ

Accessory:

No. | Item | Unit | Quantity | Remark |

1 | Main machine | set | 1 | With Printer |

2 |

Weight |

Set | 0.325 kg,1.200 kg,2.160 kg,3.800 kg,5.000 kg,10.000 kg,12.000 kg,21.600 kg | Within grade 1 load |

3 | Weight pallet | set | 1 | Within grade 1 load |

4 | Piston bar | set | 1 | Within grade 1 load |

5 | Die | set | 1 | Tungsten carbide |

6 | loading funnel | set | 1 | Stainless steel |

7 | Loading bar | set | 1 | |

8 | Cleaning bar | set | 1 | |

9 | Die Cleaner | set | 1 | Stainless steel |

10 | Gauze | roll | 2 | |

11 | Printing paper | roll | 2 | |

12 | Certificate | pcs | 1 | |

13 | User Manual | pcs | 1 | |

14 | Plate | pcs | 1 |

Automatic MFI Tester

Description:

This instrument with high precision instrument for the determination of all kinds of plastic, resin through a certain temperature and load in viscous flow state, each 10min by standard die melt flow rate MFR/MVR, polycarbonate, it is suitable for the high melting temperature polyarylsulfone, fluorine plastic, nylon and other engineering plastics, and is also applicable to PE PS, PP, ABS, POM, PC resin and other low melting temperature of the plastic test, is widely used in the production of plastic, plastic products, petroleum and chemical industries, relevant institutions, scientific research units and inspection department.

Standards: ISO1133-97, ASTM1238,GB/T3682-2000,ect.

Characteristics:

1.Three sections temperature control , 3 groups of platinum resistance sensor, 3 sets of separate heating temperature control, high precision intelligent PID control, warming slope heating speed is adjustable

2. Temperature resolution of 0.1 degrees, the temperature fluctuation within 24 hours does not exceed 0.5 degrees, the resolution of displacement sensor 0.001mm.

3. Temperature protection device

4.Automatic cutting & Manual cutting function.Can be arbitrarily set the cutting time(0~999), cutting the numbers (0~999).

5. Test can choose quality method, or volume method, or two kinds of test methods at the same time, and can calculate the flow rate ratio. The two methods are all tested when the piston rod moves to a certain position.

6. Can be set to 240 seconds (GB3682) material preheating seconds countdown, countdown to the end, automatic weight loading, loading to the specified interval to start the automatic cutting, can also set up American Standard (ASTM) such as the preheating time.

7. Built a variety of plastic melt index testing conditions, the convenience of customers at any time to obtain the use, reduce the tedious work, and store the last test conditions and results

8. Built-in printer to print the test data

9. High precision touch screen controller, 7 Inch Touch screen, can store and print the test conditions and test data recently, print menu including test time (default), material name, test conditions (temperature, weight, cutting time interval), the test result data.

10. Reserved for the RS232 interface or USB interface connected with a computer through the computer control instrument operation and the test data will be saved to the computer transmission,The weights are placed on the weight bracket in advance to realize the electric loading and unloading, and the manual operation is reduced.

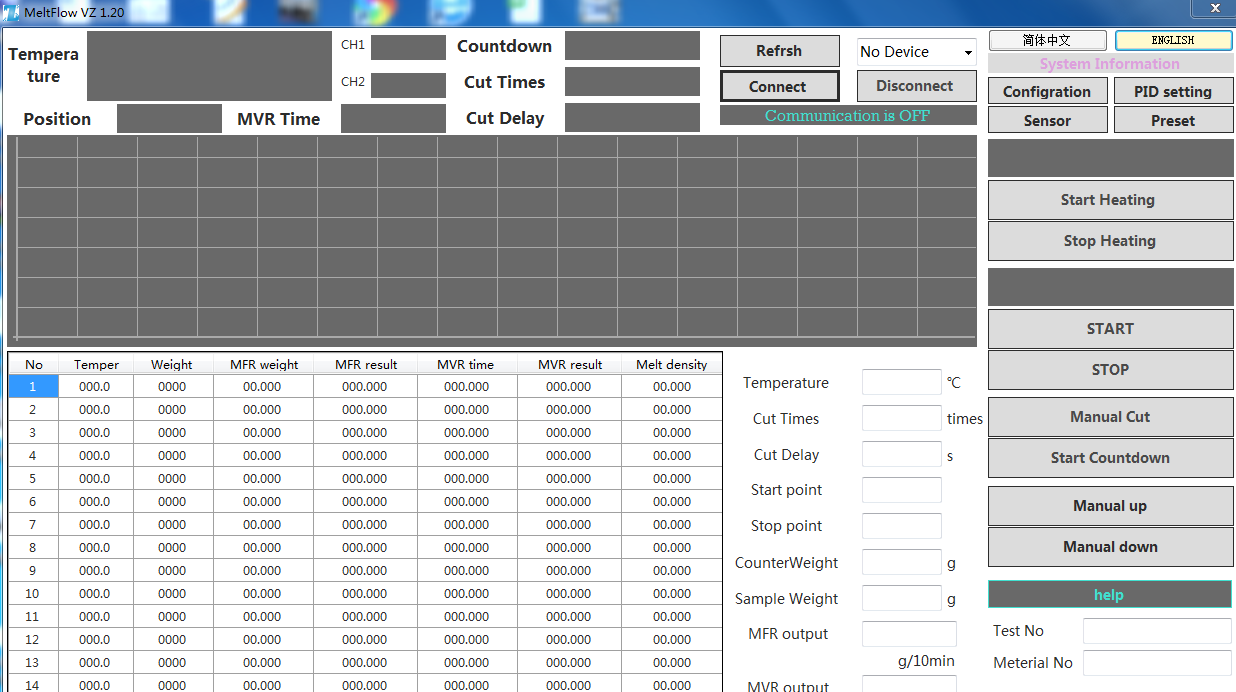

Software:

Technical parameter:

*Temperature range: 0 -450 C

*Temperature fluctuation: ± 0.2 centigrade

*Temperature uniformity:± 1

*Temperature display resolution: 0.1℃

*Time resolution: 0.1S

*Barrel diameter:Φ 2.095 ± 0.005mm

*Length of outlet: 8.000±0.025mm

*Barrel diameter: Φ9.550±0.025mm

*Weight accuracy: ±0.5%

*Output mode: micro automatic printing output

*The cutting way: automatic cutting & Manual cutting

*Test load: total of 8, 8 sets of weights

*The power supply voltage: AC220V± 10% 50HZ

Accessory:

No. | Item | Unit | Quantity | Remark |

1 | Main machine | set | 1 | With Printer |

2 |

Weight |

Set | 0.325 kg,1.200 kg,2.160 kg,3.800 kg,5.000 kg,10.000 kg,12.000 kg,21.600 kg | Within grade 1 load |

3 | Weight pallet | set | 1 | Within grade 1 load |

4 | Piston bar | set | 1 | Within grade 1 load |

5 | Die | set | 1 | Tungsten carbide |

6 | loading funnel | set | 1 | Stainless steel |

7 | Loading bar | set | 1 | |

8 | Cleaning bar | set | 1 | |

9 | Die Cleaner | set | 1 | Stainless steel |

10 | Gauze | roll | 2 | |

11 | Printing paper | roll | 2 | |

12 | Certificate | pcs | 1 | |

13 | User Manual | pcs | 1 | |

14 | Plate | pcs | 1 |